The basis of most EA farmyard inspections include checking a farm’s slurry and silage and fuel installations against the regulations. The regulations provide the rules you need to follow if you control, manage, or look after a farm or an installation on a property.

If you are expecting an EA farmyard inspection, check out our guidance at: EA inspections – what to expect when your farm is being inspected

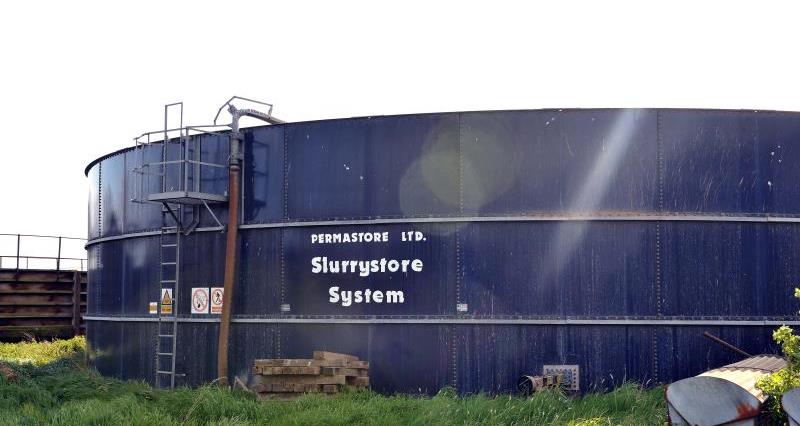

Slurry storage

Under current regulations, slurry producing farms outside of an NVZ (Nitrate Vulnerable Zone), should have at least four months’ slurry storage over the winter.

For farms inside an NVZ you must have five months’ slurry storage for cattle, sheep, goats, deer and horses and six months for pigs and poultry, which will cover the closed period for spreading manure with a high availability of nitrogen.

In addition to storing the slurry you produce, you must account for any rainfall, washings or other liquid that enters the store during the storage period as part of its capacity.

As part of an EA inspection, farms will need to provide information on slurry storage dimensions and capacity.

During the inspection the age, structure, overtopping risk, quantity of storage and any signs of potential pollution or run-off will be assessed.

Use the AHDB’s for calculating storage capacities.

Capacity

Freeboard is the vertical distance between the top of your tank or lagoon and the slurry surface.

- When you calculate the required capacity of your steel or concrete store, you’ll need to include a minimum of 300 millimetres of freeboard.

- For earth-banked stores you’ll need a minimum of 750 millimetres and you must maintain this freeboard during use. You’ll normally need capacity for at least 4 months’ slurry storage.

- Any temporary storage facilities you have – such as a reception pit – must be large enough to store a minimum of 2 days’ combined slurry production and likely rainfall.

Use the tool to work out your average winter rainfall November to February. Add an extra 25% to your calculation to take account of wetter than average winters.

Earth-banked slurry stores

An earth-banked store must have impermeable soil to a thickness of at least one metre. You may need laboratory analysis and confirmation from a civil engineer to be sure your soil is suitable. Alternatively, you can import impermeable soil or use a synthetic liner.

Separation of clean and dirty water

Water which contains any level of faecal Matter is deemed by the EA to be slurry. The separation of clean and dirty water is a key method of reducing storage capacity requirement for your system.

Diverting or capturing and storing clean water can save you money and deliver other environmental benefits.

Improving capacity and reducing emissions

In line with Defra's targets, installing a cover on your slurry store can reduce ammonia emissions, as well as helping to reduce unnecessary water ingress into the store, therefore potentially reducing storage capacity requirements. We are expecting further rounds of the Slurry Infrastructure Grant during autumn 2023.

Other solutions such as slurry separators or the separation of clean and dirty water can help to reduce pressures on your storage capacity.

Making and storing silage

Clamped and baled silage

Silage pits and/or bales will be inspected, along with manure storage sites. Clamps will be looked at for:

- condition

- age

- flooring

- drainage

- effluent collection

- signs of potential pollution or run-off.

All parts of a sileage clamp must be resistant to attack, it must have:

- an impermeable base extending beyond any walls

- impermeable drainage collection channels around the outside, flowing into an effluent tank

The base must comply with:

- and (for concrete bases)

- (for hot-rolled asphalt bases)

If your clamp has walls, they must be capable of withstanding required wall loadings. Ask your manufacturer, or check the manual that came with your equipment, to find out if it meets the British Standards.

Effluent tanks

Your clamp must have an effluent collection system.

If all parts of an effluent tank are above ground the tank must be constructed to resist attack from silage effluent for at least 20 years with maintenance.

If any part is below ground it should be impermeable for at least 20 years without maintenance. You’ll be asked to prove your tank is suitable, for example with a manufacturer’s guarantee.

Capacity

The minimum capacity rules for effluent tanks should give you at least 2 days’ storage at peak flow. You can calculate if you have enough capacity to avoid the risk of pollution.

- Up to 1,500 cubic metres = 20 litres for each cubic metre

- Over 1,500 cubic metres = 30 cubic metres, plus 6.7 litres for each cubic metre of silo capacity over 1,500 cubic metres

You must not make or store any silage or unwrap baled silage within 10 metres of inland or coastal waters.

In addition, you must not store field silage within 50 metres of a protected water supply source. This is any place where water is abstracted (taken) for any of the following purposes:

- human consumption

- use in farm dairies

- human food preparation

For information about protected water sources or use to check your local area.

Field silage or non-baled bags

You must notify the EA if you intend to make or store field silage or non-baled bags - there are specific rules which should be followed.

- Choose a suitable site; for example, if you store silage in a non-baled bag in your farmyard, you must make sure you can contain any drainage.

- Tell your at least 14 days before you first use the site.

Agricultural fuel oil

Condition of both tank and hoses, age, bunding, spill kits and any signs of potential pollution assessment will include oil storage as well as fuel.

Storage

You can store fuel oil in one location or spread across your farm. It must be stored in a tank or drum that meets . You should check the manual that came with your tank or drum, or ask the manufacturer.

No part of your installation can be within 10 metres of inland or coastal waters – including yard drains, dry ditches and land drains.

If tanks are underground, they must also follow the .

Secondary containment

A tank or drum must be surrounded by a secondary containment structure or bund. To find out the requirements for secondary containment structures, visit:

New storage systems

You must tell the EA (Environment Agency) of any new storage for silage, slurry or agricultural fuel oil, or to an existing store structure, 14 days before you begin construction.

The EA will then inspect the planned store or modifications to ensure they comply with the rules.

Exempt storage and building standards

If your installation was built before March 1991, or a contract for construction was entered into before March 1991 and completed before September 1991, .

The EA retains the right to serve notice on any storage facilities which are believed to represent a risk to pollution, requiring you to bring storage up to the current standards if it believes there’s a significant risk of pollution.

However, if you make substantial changes, for example structural changes, increasing capacity or relocating your store, it is no longer exempt.

Pre 1991 stores are still required to have 5 months storage in an NVZ.

Environment Agency Notification

When you wite to the EA you will need to tell them:

- your name, address, telephone number and email address

- the type of store you’re proposing to build or change

- the exact location of the site (8-figure grid reference)

For the EA to assess your proposal you’ll need to supply:

- a site plan drawing of the structure

- a design drawing confirming the materials that will be used and their design, specification and layout – you may also be asked to confirm that your design meets the requirements of BS 550 building standards from the installer.

- if you plan to use prefabricated products, a copy of the manufacturer’s specifications and guarantee

- if the structure is constructed from earth, analysis about the soil type, depth and permeability and a description of how it will be engineered

- for underground, or partially underground silage effluent tanks, you’ll need a certification from the installer – you must provide this certification to the EA because the tank is required to perform for at least 20 years without maintenance

You’ll usually get a written assessment of your proposal that says whether it’s been approved or not. The EA may contact you, rather than giving you a written assessment, to give you guidance on changes you need to make to your installation before it can be approved.